Introduction

Compressed air systems are integral to the daily operations of a wide range of industries, from manufacturing to food processing. These systems provide a powerful, versatile source of energy for everything from pneumatic tools to automated machines. Given their prevalence and importance, optimizing compressed air systems has become a key consideration for businesses seeking to enhance efficiency and minimize operational costs. Even minor improvements in these systems can lead to significant energy savings and reduced downtime, making them a growing focus among industrial leaders.

Companies searching for air compressor products Jacksonville, FL often realize that significant performance improvements are not only possible but essential for maintaining competitiveness in an increasingly resource-conscious landscape. By adopting new technologies and following proven best practices, industrial operators can dramatically increase the reliability and sustainability of their compressed air systems, ensuring peak performance throughout their lifecycles.

Understanding Compressed Air Systems

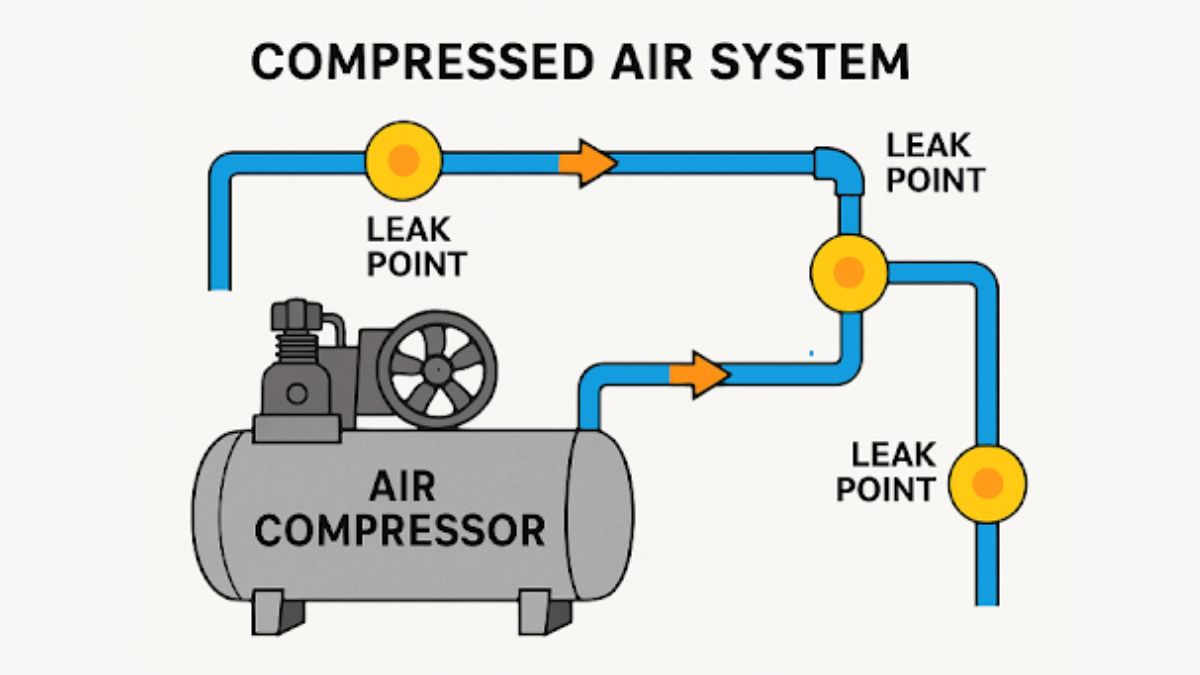

Compressed air systems typically consist of an air compressor, air treatment components, storage tanks, and a distribution network. The compressor draws in ambient air, compresses it to a higher pressure, and delivers it for use throughout the facility. Air is temporarily stored in tanks and then passes through filters and dryers to remove moisture and contaminants. These systems supply power for a variety of industrial applications, such as material handling, spray painting, instrumentation, and process automation.

The versatility of compressed air systems makes them a vital utility, much like electricity or water. However, they are often the most expensive utility in a plant environment due to their high energy consumption and the potential for undetected waste. Recognizing these factors underscores the importance of implementing strategies that improve the efficiency and reliability of compressed air systems.

According to the U.S. Department of Energy, compressed air systems can account for up to 30 percent of a facility’s total electricity use, with as much as half of that energy potentially lost to leaks, improper pressure settings, or inefficient equipment. Leaks alone may result in energy losses of 20-30% in a typical plant. These inefficiencies not only increase energy costs but also raise the risk of equipment failure and unplanned downtime.

Best Practices for Optimization

Leak Detection and Repair

Regularly inspecting the compressed air system for leaks is one of the most effective ways to reduce waste. Techniques for leak detection include ultrasonic testing, applying a soap solution, and scheduled manual inspections. Promptly repairing even small leaks can result in substantial energy savings and extend equipment lifespan.

In addition to energy savings, effective leak management improves overall system reliability and helps maintain stable pressure, which is critical for sensitive industrial processes.

System Pressure Management

Running a system at unnecessarily high pressures increases energy consumption and component wear. It is best practice to operate compressors at the lowest possible pressure that meets production demands. Using pressure regulators and advanced controls allows companies to match system pressure to varying demand throughout the production cycle.

Lowering system pressure by as little as 2 psi can cut energy costs by up to 1%, translating into substantial annual savings, particularly in large-scale operations.

Proper Equipment Sizing and Maintenance

Selecting appropriately sized compressors and air treatment equipment ensures the system operates efficiently. Oversized compressors cycle too frequently, leading to excess energy use and mechanical wear, while undersized units struggle to meet demand, resulting in pressure drops. Routine maintenance, such as filter replacement and lubrication, ensures components function optimally and reduces the risk of unexpected breakdowns.

Developing and following a comprehensive maintenance schedule is essential to maximize return on investment and ensure uninterrupted service.

Utilization of Advanced Control Systems

Smart controllers have revolutionized compressed air management by enabling real-time system monitoring and dynamic adjustment of compressor output. These systems can analyze demand patterns and automatically adjust to minimize energy use and prevent costly system overruns.

Case studies from the Better Buildings & Better Plants Initiative demonstrate how industries have used advanced controls to achieve energy savings of up to 20 percent, along with improved reliability and operational flexibility.

Innovative Technologies in Compressed Air Management

Recent years have seen the emergence of artificial intelligence (AI) applications in compressed air management. AI-based solutions can analyze vast amounts of system performance data to identify patterns, predict maintenance needs, and optimize operations. These tools enable predictive maintenance, alerting operators to potential issues before they cause costly downtime or drive up energy costs. AI also assists with system design, equipment selection, and adaptive control, ensuring resources are used as efficiently as possible.

Final Thoughts

Optimizing compressed air systems represents one of the most accessible and impactful opportunities for industries to improve efficiency, reduce costs, and strengthen reliability. By following best practices such as regular leak repair, pressure management, and proper maintenance, and by embracing technological advancements like AI and smart controls, companies can build a foundation for sustained operational excellence. Investing in the optimization of compressed air systems pays dividends in both the short and long term and positions organizations to succeed in a competitive, sustainability-focused industrial environment.